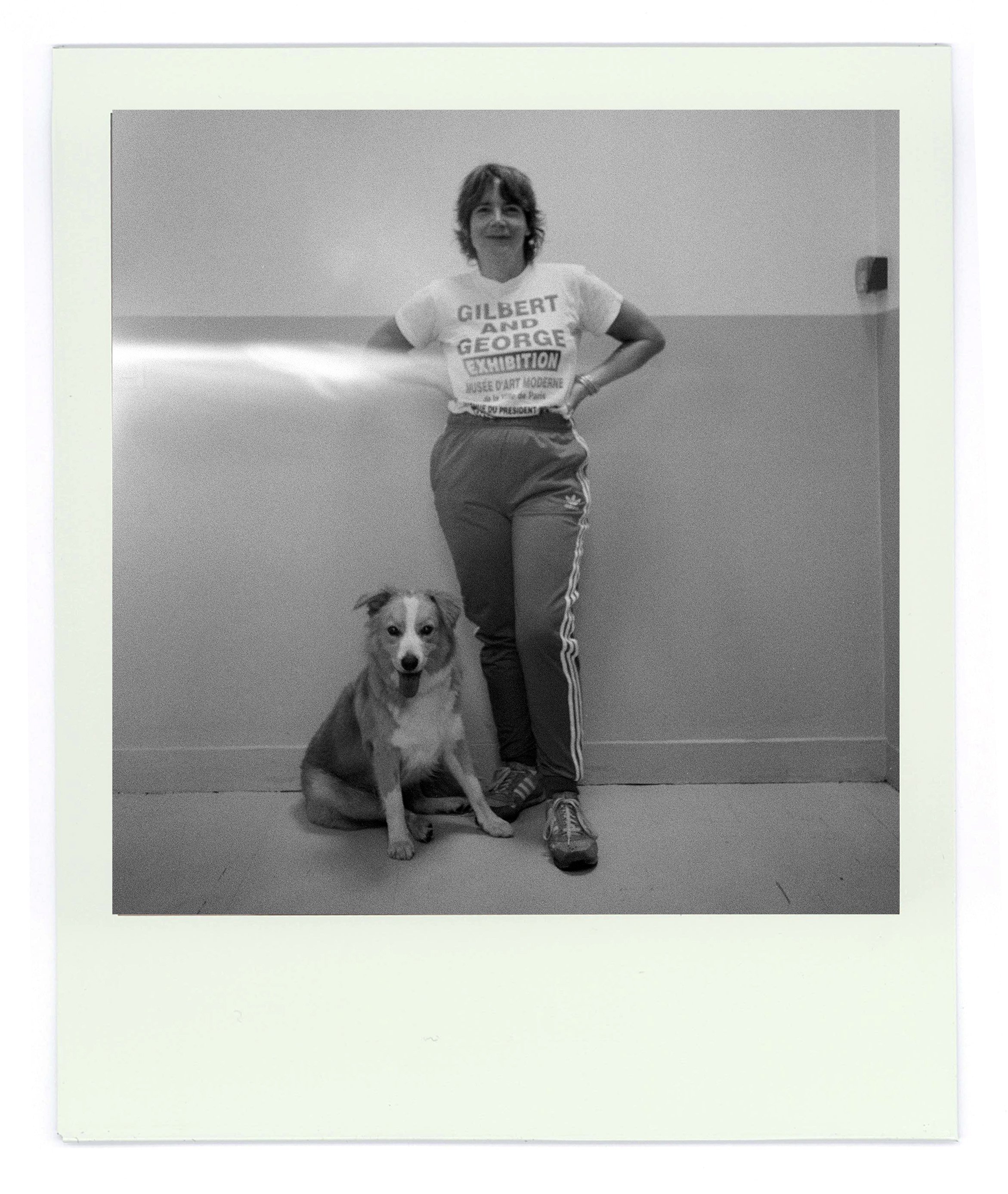

IN THE HEART OF THE HIVE

A visit of the agnès b. workshop which designs the prototypes and the patterns of the women, men and children lines. Discover to the heart of the house.

(By Camille Dorval)

Entering the workshop at 15 rue du jour is not dissimilar to stepping into a beehive or an anthill. Everyone is running around, focused on his or her task. ‘And the queen, for whom they are so hard at work, it’s Agnès!’ Adds Marie-Reine, one of the workshop heads.

The workshop employees are deployed around a vast plateau, making it just the one room. One one side, sewing machines and mannequins: it’s the kingdom of the modellers and the sewing workers who are on the frontline of the creation of prototypes. On the other side, giant computers and printers, which develop the patterns: there work the modeller CAO (or CAC, for Computer Assisted Creation), whose job is to ensure the creation of the clothes. ‘Few tailor shops, especially the ready to wear ones, still have a prototype workshop like we do, says Marie-Reine. It’s specific of Agnès b.’ In fact, more than a mere workshop, it really is a study office, which intervenes in various parts of the creation of the house’s clothes.

The prototypes shuttle

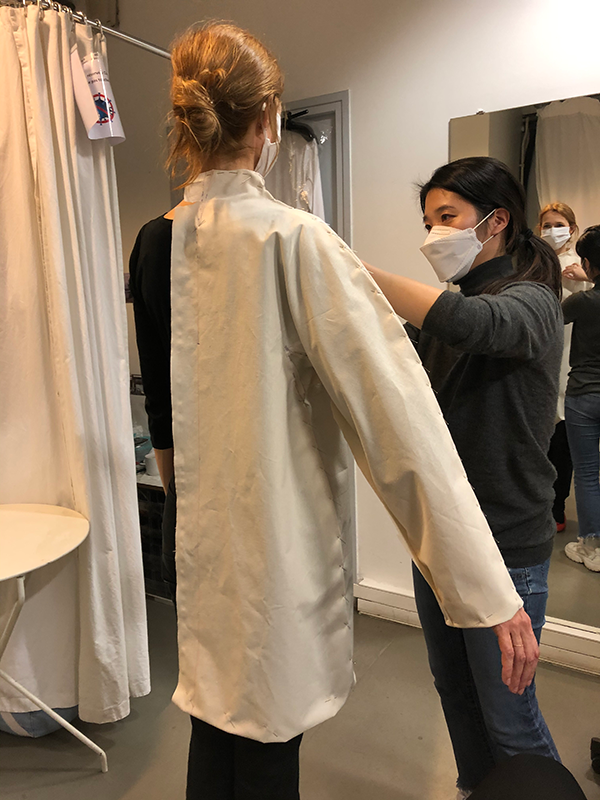

First step: the design of the clothes’ prototypes by the creation team of the workshop, ruled over by Marie-Reine, after Agnès’ drawings. Since the inception of the shop, Agnès is the only stylist on board and designs all the clothes. Corinne, the modeller, interprets those drawings in volume, by creating the corresponding clothe on a mannequin. This first draft is shown to Agnès, who might send it back several times before approving the model. The team is also in charge of the fabric that will be used to craft the garment. Angès likes to use fabric of which she oversees the patterns, based of photographs she takes in her garden, in the street, or on one of her many trips abroad. ‘We then have the fabric printed specifically for us,’ explains Marie-Reine. In the summer 2022 line, for example, a dress and a bustier were adorned with a black and white photograph of a garden, taken by Agnès, and the workshop had to made sure the fabric ‘fell’ right on the garments once the pieces were integrated with one another.

After this part of the job, prototypes are then made with the fabric picked by either the manufacturers or by the sewing workers of the workshop - who also have the title of ‘mechanics’ since they work on sewing machines. ‘We discuss a lot with the hand modeller top find ow to show the garment technically, then we suggest tweaks and ameliorations, explains Georgette, a seamstress for agnès b. For the past 30 years. It’s subtle work. Agnès b. Is very demanding in terms of quality.’ ‘It requires tremendous efforts of precision and patience, adds Christine, a seamstress who has been working here since 2014. But we work alongside motivating people, who appreciate a work well done. It’s very gratifying.’

Preparing the clothes for ‘real life’

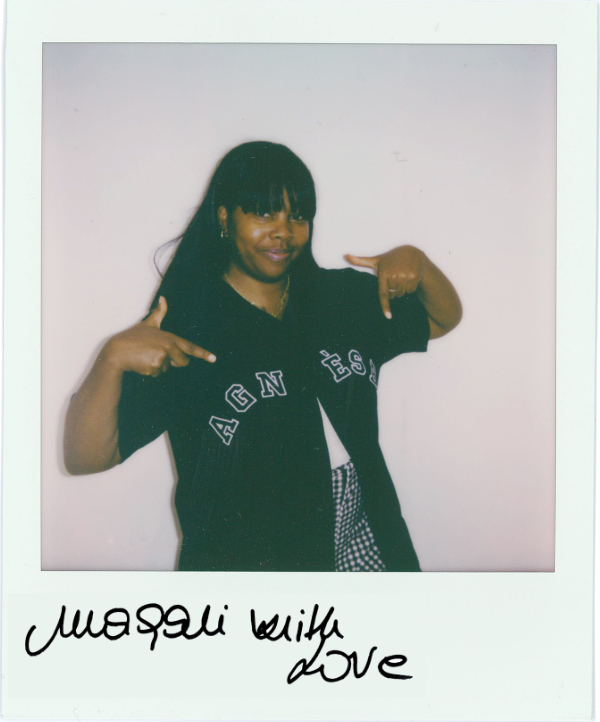

After the fashion show or the presentation (these last seasons, agnès b. Has favoured video formats, such as this one) the commercials of the house select the models that they will offer to the angès b. Boutiques around the world. Then the boutiques’ heads make their order of the model and size they desire according to their clientele. Once the list is known, the models can be reworked by Marie-Reine’s team, which adapts them to the morphology of everyday people, while the prototypes were designed on mannequins with specific dimensions.

Then it’s the other team of the workshop, the one in charge of industrialisation, which steps up, led by Masayo, who started with agnès b. In the late 1980s. Then the CAO modellers of the workshop are tasked with digitalising the patterns on computers in order to make it available in various sizes, from 34 to 44, calculating the amount of fabric and accessories necessary to create the clothes, drafting the technical drawings, writing down on a technical note the sewing, the lining, or even the choice of buttons. The CAO team also ensures that the required fabric is used so that not of it goes to waste, on which the workshop keeps a watchful eye. In case of an overload of fabric, it’ll be used in another capacity.

CAO modellers then convene with the manufacturers directly. From the technical form, they create a new model that the workshop studies from all angles. Once the back and forth is done, the manufacturers creates a new model based on these observations. ‘And on and on it goes until we create the perfect piece,’ says Linah, a CAO modeller. ‘Sometimes we even have to build up drafts to help the manufacturers,’ adds Zakia, also a CAO modeller, in charge of the children line as well as the leather line. Once all these problems are solved, the garment can be built continuously, and ordered by scores of boutiques.

Agnès can intervene at any stage of the creation or production process. ‘She deeply respects our work, says Masayo. She leans to all the comments we can give her. That’s a rare thing in fashion.’ ‘The employees are proud to work for agnès b. Say both Marie-Reine and Masayo. Firstly because it is a family business, that still belongs to Agnès and her children. But also because Agnès cares about us, hence we care about her.’ For the two heads of the workshop, ‘it’s in great part why the teams are that faithful and devoted to the company.’ It is also probably the key to agnès b.’s success for nearly 50 years.